Details

Details

Details

Details

Details

Details

Details

Details

State-of-the-art

Our mica components can resist temperatures of over 1000 °C for more than 15 minutes. Therefore, they are an effective burn-through barrier for all common battery cell types. Molded in 2D or 3D and fully compatible as an insert for common aluminum or steel battery covers.

Evolution

Faster, more efficient, functionally integrated. These are key requirements for next-generation battery covers. Our SMC (Sheet Molding Compound) covers with integrated mica burn-through protection are the best solution. SMC battery covers are far superior to current solutions due to their technical performance.

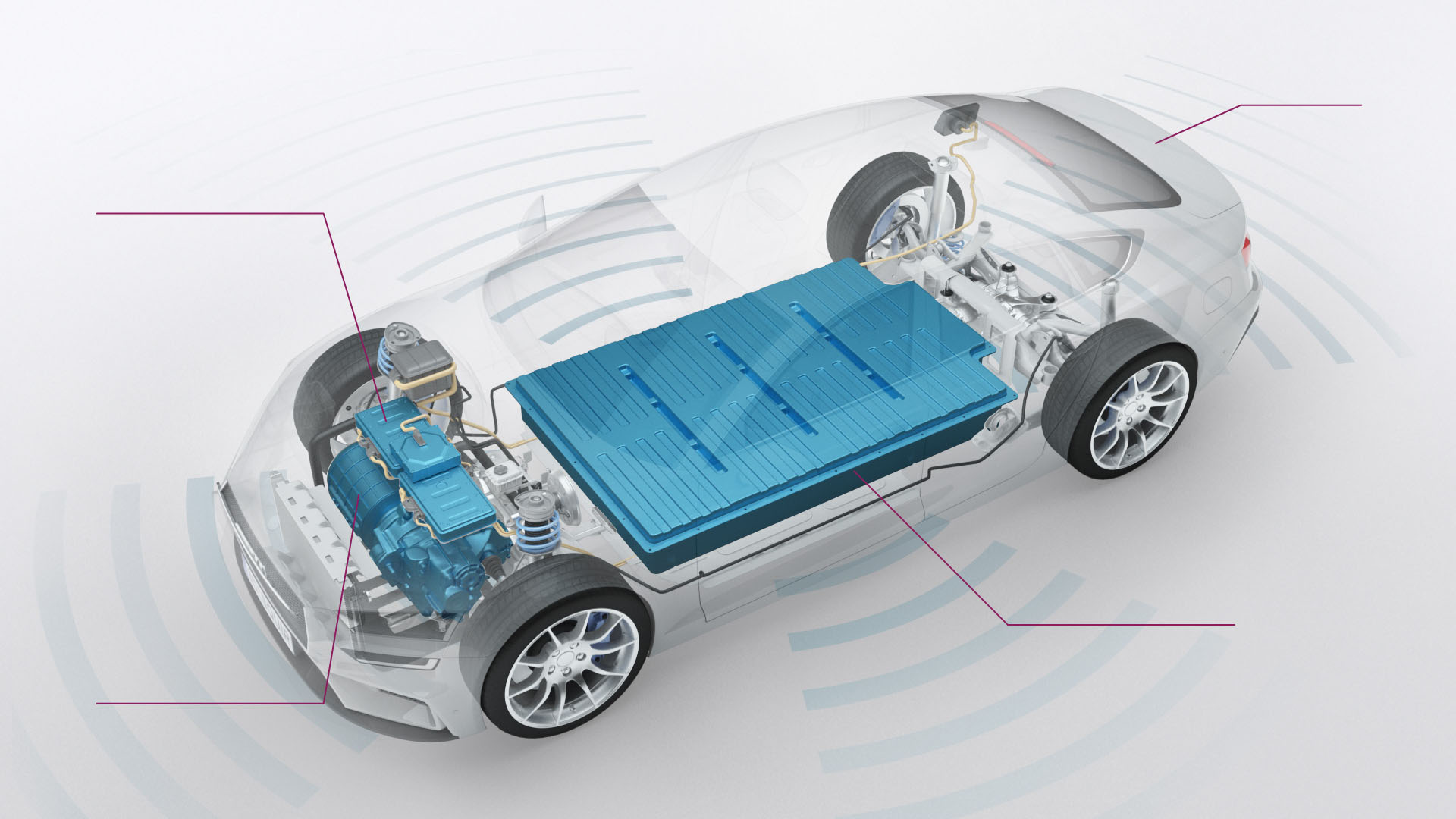

Revolution

A system solution for hybrids or all-electric vehicles. Modular, flexible, and suitable for any battery design. Engineered for high-performance cells, this fully integrated solution already meets future safety requirements.

Gas discharge

We have developed Mica tubes for battery applications that can exhaust hot gases generated by a battery fire.

Module and cell cover

Our Shield T® series features the best resistance against high temperatures, abrasion, and oil. As a result, the spread of a battery fire can be successfully delayed or prevented. Shield T® is already in series use worldwide, setting new safety standards for electric vehicles.

Cell spacer

Von Roll’s Cell Spacers are composite components for battery protection. They prevent thermal runaway events through excellent thermal and electrical insulation as well as fire protection. At the same time, they are highly compressible depending on the state of charge, and this can be accurately reproduced millions of times.

Electrical laminates

Our high-performance insulation films effectively prevent short circuits in high-voltage applications. Our product families Myoflex® and Acuflex® have a very high dielectric strength as well as maximum thermal and chemical resistance.

Cell potting

Do you need a simple solution for interfacing battery cells to your thermal management system? We have combined the properties of a gap filler with those of an adhesive.

With our worldwide unique Damival® 1368X product series, significantly higher power densities can be achieved due to the excellent thermal conductivity. The adhesive properties eliminate the need for additional fixation of the cell and enable extremely short cycle times. In addition, our "Potting Adhesive" is self-extinguishing in case of fire. You will not find anything better in the market.

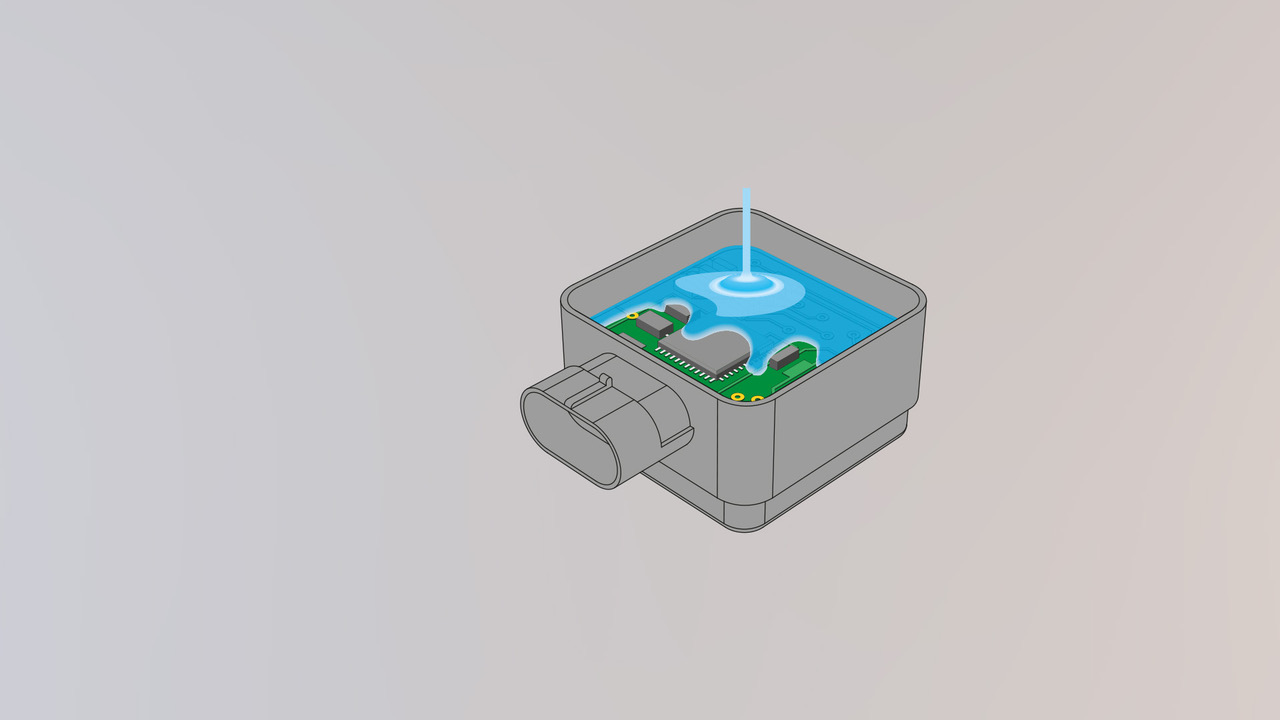

Conformal coating

Our protective coatings for electronics are single-component systems and thus easy to process. The Synthite® and Damitron® series require low curing temperatures and short curing times – ideally suited for fast-cycle and cost-efficient manufacturing processes. Our latest urethane coatings are solvent-free, environmentally friendly, and UV-curable.

Battery cover

Battery cover Back

Back