IMPREGNATION RESINS

Our impregnation resins are the best choice for winding insulation. They offer the best electrical, mechanical, and thermal protection of coils such as those used in pumps, transformers, EV drives and wind turbine generators.

All of our current impregnation products represented by the Dolphon® and Damisol® brands are UL listed while meeting the highest technical requirements. Our most innovative resin systems are label-free, hazardous material-free, feature improved heat dissipation and are 100 % resistant to partial discharges.

Our extensive technological base with polyester, epoxy and silicone resins enables us to offer customized solutions to our customers.

Products and solutions

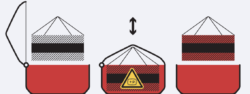

The trickle and dip rolling process is particularly suitable when short cycle times have to be realized, as required for series production with high output.

Here, our resins of the Dolphon® and Damisol® series enable a particularly fast and clean production process. This makes them particularly suitable for high-volume industrial production and the automotive industry.

Dipping represents a relatively simple process that requires little investment and, with the right resin, leads to a good impregnation result. With our Dolphon®, Hi-Therm® and Aqua-Therm® resin solutions, fast and high-quality impregnation can be guaranteed.

If higher impregnation qualities are required, as is the case in the production of medium-sized industrial motors or the premium segment in the automotive industry, the process of hot dipping is often used. With our novel technologies and customized products of the Dolphon® and Damisol® series, dipping costs can be reduced by up to 40 % while improving performance.

Wind turbines, generators and traction machines all share the need to operate in harsh environments and provide reliable operation over a long service life. These applications require an outstanding impregnation quality, which is usually achieved by vacuum-pressure impregnation.

To guarantee the best impregnation quality, an impregnation resin needs to be paired with fine-tuned process parameters. Our experts offer you an excellent resin selection from the Damisol® series coupled with many years of process expertise.

For the insulation of machines in extreme environments, we recommend our Damival® and Dolphon® potting resins using the complete stator potting process. This provides optimum protection for the electrical machine and the best heat dissipation.