Focus

Top Employer

Midsize Company

Germany

HR Excellence Award

2022 Nominee in

Candidate ExperienceServiceValue

Best Employer

Switzerland

Kununu

Top Company

2022/2023

Germany, Switzerland

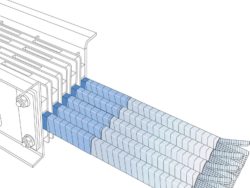

Aerospace

Electrical appliances

Presses & smelters

Automotive

Electronics

Paper industry

Traction drives

Hydro generators

Protection & safety

Battery

Industrial drives

Transportation

Fire-resistant cables

Engineering

Turbo generators

GenSets

Medical devices

Wind power

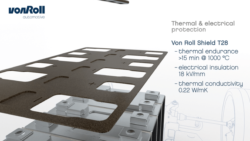

Von Roll Group

Our work has stood the test of time for nearly two centuries. We are a global player and technology champion based in Switzerland.

As the industry leader for electrical insulation systems, we are driving the global electrification. Our products are essential for the ongoing industrial transformation to zero emissions.