VON ROLL INSIDE

MAKES THE DIFFERENCE

The use of electricity in electrical machines and devices is not possible without a customized insulation system. In addition, sensitive electronic components must be protected against mechanical stress and environmental influences.

We have developed the best solution to meet these requirements. Our team of experts works closely with well-known brands and global market leaders. For more than 100 years, even the most demanding customers have been impressed by our products

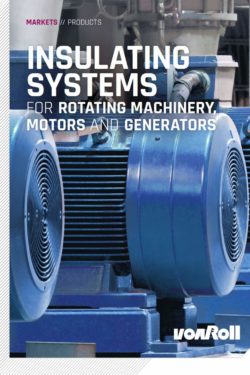

Converting high voltage into high performance

Wind and water carry enormous amounts of energy. Our insulation systems are enabling generators to convert this massive power into electricity. And conversely, when motors need to transform electricity into mechanical power, our insulation solutions are essential too.

Von Roll insulation systems for high-voltage applications are a powerful booster for motors and generators. They make a huge contribution in permanently improving the efficiency, performance and durability of electrical machines.

Our one-system approach simplifies the complex interaction between high-tech insulation tapes, high-performance composites, resins, varnishes and wires. We are the only manufacturer in the world providing all these components and tailor-made solutions from a single source.

Systematically matched

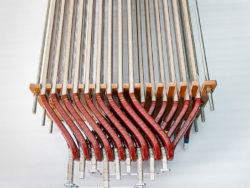

Electrical insulating tapes

Mica tapes are the key elements for the main insulation of high voltage machines.

High-voltage resins

Resins provide protection against moisture and vibration wear. They also increase dielectric strength.

Composite materials

Composite materials reinforce the mechanical stability of the winding.

Wire components

In our state-of-the-art coil manufacturing facility, we cover the entire value chain from flat wire to fully insulated coils.

SELECTED FIELDS OF APPLICATION: We are technology leaders in various fields

Our solutions are built-in to the largest hydropower plants in the world.

Our solutions for nuclear, coal‑, gas- or oil power plants

The limited accessibility and harsh conditions set highest demands for the reliability of insulation systems used in wind power generators.

Von Roll actively supports manufacturers in their efforts to improve the efficiency and power-to-weight ratio of AC and DC motors, transformers, etc.

Our solutions enable large industrial machines to achieve higher performance and reliability at lower manufacturing costs.

Diesel engine generators operate under highly volatile loads and heavy conditions including strong vibrations and extreme temperatures. We provide reliable insulation systems for all electrical components.

More efficient

We are experts in maximizing the thermal and electrical capacity of the insulation system — improving the efficiency of your machines.

Stronger & more compact

Due to the improved efficiency, your machines will provide more power at the same size — or you can opt for a more compact design.

More durable

Your machines will feature a longer operating and service cycle — thanks to higher resistance against thermal, electrical and mechanical stress.

Cost-optimized

We provide you with optimized all-in-one systems, which reduces material costs and simplifies the serial production of your electrical machines.

COIL PRODUCTION IN INDIA

From raw materials to integrated, ready-to-install components

The market for rotating electrical machines, generators and motors is experiencing a strong outsourcing trend — driven by major manufacturers. We have expanded our existing plant in Bangalore into one of the most modern production facility for electrical coils in India. This has strengthened our position as a producer of integrated and ready-to-install system components.

Von Roll is the only company in the electrical insulation market to cover the entire value chain from raw material extraction to ready-to-install wire coils as a one stop shop. Controlling the entire process enables us to develop unique products with the highest quality standards. In close cooperation with our experts in Breitenbach, our Indian facility now also offers technical design, complete system tuning and manufacturing of entire coil components.

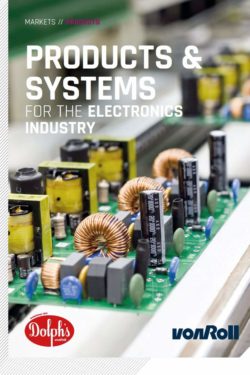

Strong protection for sensitive technology

Without even knowing, you have probably already come into touch with one of our products today. Either in your car, in your home, or in industrial production. Wherever electrical devices and electronic components are used, our resins play an essential role. They protect sensitive technology in an effective and very eco-friendly way. At the same time, they enhance durability and performance significantly.

In the course of Industry 4.0, digitalization and electrification, the demand for motors, sensors and electrical components is rising rapidly. As a leading specialist for innovative resin systems, we support manufacturers worldwide in staying ahead of these trends.

We stand out in particular with our high-performance range of solvent-free, green resins. They are extremely easy to apply and enable our customers to achieve technical progress in a way that is kind to human health and our climate.

With R&D centers in Europe and the USA, Von Roll is a technology leader and has a strong innovation track record. Our research teams work closely with well-known brands and global market leaders on specific customer projects.

PROTECTION FOR ELECTRICAL COMPONENTS: Our expertise for over 100 years

Impregnating resins

Impregnating resins are used to protect and stabilize inductive windings in motors and generators.

Potting resins

Potting resins protect electronic components from environmental impacts and overheating.

Insulation papers

Sheet insulation materials are used in motors and electrical equipment as part of the main insulation.

Protective coatings

Protective coatings cover printed circuit boards and electronic components to protect them from environmental impacts.

SELECTED APPLICATIONS: WE ARE TECHNOLOGY LEADER FOR INSULATING RESINS IN VARIOUS FIELDS

Industrial automation

Industry 4.0 demands highest efficiency and endurance of industrial drives, sensors and electronics. Our newly developed resin systems offer unique advantages and solid protection.

Electrical appliances

The push for more powerful electrical appliances featuring ultra-compact motors creates high engineering challenges. Our impregnating resins protect motors and electronics in such devices even at maximum speeds and under harsh environments.

Automotive

Insulation resins are used in a wide range of applications for modern vehicles. They are essential for the reliable operation of electronics, sensors, batteries and e‑motors.

Electronic components

Our resins provide electronic components with high levels of protection against environmental influences. Thanks to excellent heat dissipation, they enable more compact designs, e.g. for transmitter modules in 5G networks.

INNOVATIVE & ECO-FRIENDLY: GREEN RESINS IN GREAT VARIETY

Are you looking for cost-efficient solutions for large scale serial production? Our innovative systems can be tailored very specifically to any desired application.

The Dolph’s® product portfolio is extremely versatile and includes, among others, the well-known brands Dolphon®, Hi-Therm® and Aqua-Therm®.

Dolph’s® does not only stand for over 110 years of experience. It has also been pioneering the development of particularly environmentally friendly formulations for decades. A majority of our resins are already free of solvents and hazardous substances. Some of them are even completely label-free.

With outstanding service, Dolph’s® supports customers around the world in their efforts to combine maximum functionality with highest standards of sustainability.

The chemistry is right.

Peek inside our InnoLab!